Lambeau Field, Wisconsin, USA

Feb 20, 20

Lambeau Field, Wisconsin, USA

Sporting Events and Construction Continued Side by Side. Both Scored Well

Lambeau Field, home to the National Football League’s Green Bay Packers, has sold out every single game since 1960. Demand for tickets remains high, with more than 112,000 names on the season ticket waiting list—an average reported wait time of more than 30 years.

Understandably adding seating capacity to the stadium was a high priority initiative.

In early 2012 a plan was put into motion to add 7000 more seats for eager fans.

The Challenge

Operating without disturbing the fan experience.

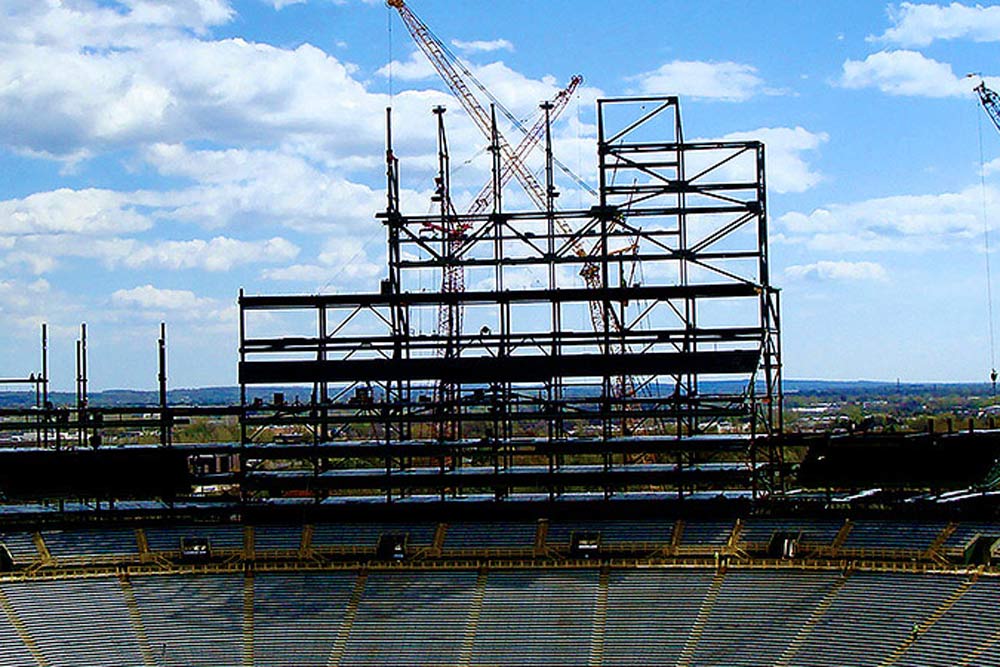

Work in progress at the Lambeau field - home of the Green Bay Packers

The Solution

In addition to the South End expansion, over the past few years, Lambeau Field has undergone numerous upgrades, including adding a new team area and expanding an entrance. Over the past year, the facility added a new east gate – the American Family Insurance Gate, built a new Harlan Plaza and Packers Pro Shop, and will complete a build-out of a restaurant and Hall of Fame. Miron has used, or will use, Putzmeister’s 52Z-Meter on each of these phases.

“The expansion and renovation of Lambeau Field is a project that has improved the gameday experience for all our fans,” said Packers President/CEO Mark Murphy. “It was important to not only improve the experience, but we also were able to bring more fans to games with the addition of the South End. It’s improved our home-field advantage and makes the environment even more electric.”

Preserving the Fan Experience

Thousands of fans tour Lambeau Field each year, and parts of the facility are rented out for social and business events year round. It was essential that the construction at the stadium did not interfere with any of those events, so the crew had to work around facility operations.

“The Packers are all about the fan experience,” explained John Murphy, project executive with Miron. “We had to be extra conscientious about our surroundings and limiting our presence around certain areas of the job site.”

Extensive Prep Work

Before concrete could be placed, Miron, who also served as the project’s general contractor, was tasked with taking down the existing scoreboard that currently resided at the top of the structure. The new seating area, which would top out at 10 levels, along with the new scoreboard, would be built on top of the existing highest level, level three. Upon completion, from ground level to the top of the new scoreboard measures more than 70m.

After the old scoreboard was removed, structural steel was erected in five different sections. Because the new scoreboard had to be installed by a certain date—much sooner than the rest of the project would be complete—the center section of the steel that would hold it had to be erected first. The crew worked with engineers to put in temporary framing on levels seven and nine, and poured concrete prematurely on level seven in order to get the scoreboard up on schedule.

“Logistically, it was a challenge to erect the massive scoreboard before the rest of the structure was in place,” said Murphy. “It took a lot of planning and coordination, but the end result was a success.”

The crew knew it would be a challenge to add the weight of the concrete on top of the massive amount of steel—5,500 tons—required to support the new structure. A lightweight concrete mix would prove essential.

Level by Level, Seat by Seat

After reinforcing the structure, the crew prepared to place concrete for the seven stories of seating areas and concourses they were adding to the top of the South End. They were on a tight schedule, as certain parts of the project needed to be operational for the upcoming football season. This part of the project was also built in sections, so the Packers had access to them, even while the rest of the project was still under construction.

The structure and beams for the seats were set up for Miron—now the concrete just needed to be placed. The boom of the Putzmeister 52Z-Meter was able to reach all the way from ground level up to level nine—nearly 37m in the air.

“The 52Z-Meter’s long reach worked out perfectly for this project,” said Murphy. “We were extremely happy with the pump’s performance at that great height.”

“We knew the project and the timing was going to be a challenge in many respects,” the Packers’ Murphy said. “We needed to continue to play games and work in the stadium, and the construction team did a phenomenal job making that happen. We really appreciate everyone’s professionalism. It was seamless from our end.”

Developing the Right Mix

The existing weight of the stadium structure the construction team was adding onto made the use of a lightweight concrete mix essential. Miron worked closely with the team at Carew Concrete & Supply Co. for months to develop a special mix, plus ad mixture called ELEMIX, that would work for this application.

“Not only did the concrete mix need to be lightweight due to the mass of the structure, but it also had to be adjusted to enable it to be pumped to high elevations for the seating areas,” said Murphy.

ELEMIX is an innovative concrete additive made of specially engineered polymeric spheres—lightweight synthetic particles—that disperse uniformly throughout a concrete mix to replace a significant volume and weight of both normal and lightweight aggregate. It evenly disperses throughout a mix to ensure uniform strength. When designing low density concrete, ELEMIX can assist in the controlled reduction of concrete density, an essential component to this project.

“As far we know, ELEMIX has never been pumped to these heights—a maximum of nearly 37 m,” said Murphy. “It was quite an accomplishment to have created just the right mix for the height and weight of this project.”

The Final Product

The South End expansion added 31,215 m2 to Lambeau's previous size of 157,935 m2. The project featured approximately 7,000 new seats, all theater-style chairs with backs, with many providing a stunning aerial view of the historic stadium. Roughly 5,4000 of the 7,000 seats are considered general seating, with the other 1,600 in the premium category as club seats or terrace suites, as well as sponsor and partner areas.

"It has been an honor to work on such an important, meaningful structure" adds Murphy.

All phases of the Lambeau Field Development project should be wrapped up in mid-2015.

From ground level to the top of the new scoreboard measures more than 70m.

The boom of the Putzmeister 52Z-Meter was able to reach all the way from ground level up to level nine—nearly 37m in the air.

The South End Zone expansion added 7000 seats to the iconic stadium.

Concrete Takeaways

- Lambeau Field is also known as ‘The Frozen Tundra’.

- The South End expansion added 31,215m² to Lambeau’s previous size of 157,935m².

- Of the 7,000 new seats, roughly 5,400 are considered general seating, with the other 1,600 in the premium category as club seats or terrace suites, as well as sponsor and partner areas.

- Putzmeister’s 52Z-Meter was also used on other upgrades to Lambeau Field, including a new team area and a new east gate.

Specs

Owner/Developer: The Green Bay Packers – Green Bay, WI

General Contractor: Miron Construction Co., Inc. – Neenah, WI

Equipment Owner: Miron Construction Co., Inc. – Neenah, WI

Ready Mix Concrete Provider: Carew Concrete & Supply Co. – Appleton, WI

Equipment: (1) Putzmeister 52Z-Meter Truck-Mounted Boom Pump