Siam City Cement: Delivery of industrial waste into cement kilns

May 17, 22

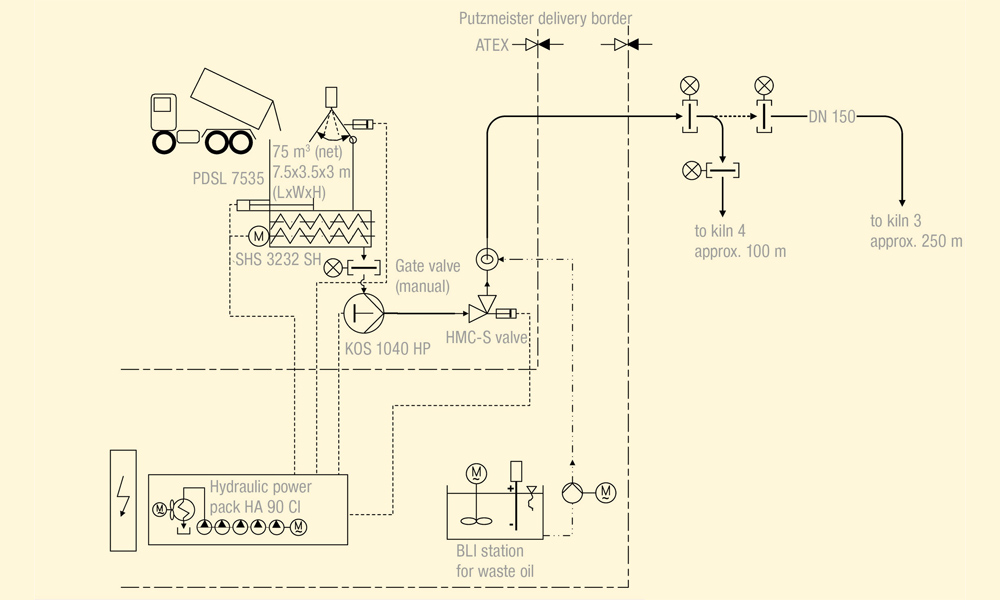

Siam City Cement have chosen to use a Putzmeister piston pump to inject different kinds of industrial waste into the cement kilns at their Saraburi site in Thailand.

The pumping arrangement has the major advantage of being a closed system, which means there is no opportunity for material to contaminate the surrounding environment. A further advantage of the system is the ability to easily adjust the output of the pump in accordance with the heating demand from the kiln, therefore giving a very efficient combustion cycle. The whole installation has also been designed to conform to ATEX specifications.

KOS 1040 HP piston pump

Paint Sludge

Reception silo

Siam City Cement also chose a Putzmeister sludge reception system to work in conjunction with the material pump. The reception silo has two hydraulically driven lids, and is configured to receive different kinds of industrial sludge delivered by truck. The sludge will be discharged from the silo using Putzmeister sliding frame and double screw auger technology, into the Putzmeister KOS 1040 HP piston pump. The KOS 1040 HP can then convey a range of different sludges over the required distance of 100 – 150 m into either of the two different cement kilns on site. Siam City Cement are using Putzmeister equipment to pump a wide range of different industrial sludges such as:

- Oil sludge

- Paint sludge

- Glue

- Waste water sludge

- Drilling mud

- Filter cake

- Distillation residue

The following machinery has been delivered to the Saraburi cement plant:

- PDSL 7535

- SHS 3232 SH

- KOS 1040 HP

- HMC-S valve

- HA 90 CI

- BLI station

The KOS 1040 is operating 24 h/day with a capacity in the range of 1 – 5 m³/h. The operating pressure of the pump is between 35 and 80 bar depending on the material. The connecting pipeline between the KOS and the two kilns is 100 – 150 m long, and has a diameter of 150 mm.

Sludge reception hall

Silo lid