How to take care of your Investment?

At Putzmeister, we guarantee that our high-quality equipment can handle even the toughest challenges. But even the very best equipment can only deliver optimum performance if it is regularly maintained. We are always there for you to ensure long and smooth operation.

We know what downtime could mean for your schedule, for your money and for your reputation.

And that's why it's essential for the protection of your investment and the safety of your workers that your equipment is regularly checked by service experts. We work with customers from all over the world and the experience of many years has shown us that many machines would not have broken down in the first place if they had been subject to regular maintenance inspections.

Do you want to extend the life of your machine? Here are some tips for maintaining your equipment!

To be on the safe side, you and your operators can contribute to a long machine life by following these steps:

Firstly, carry out maintenance work of your machine, according to operational conditions and working situations. Conduct this exercise regularly as per your machine maintenance schedule. Use genuine parts only from Putzmeister or Putzmeister dealers.

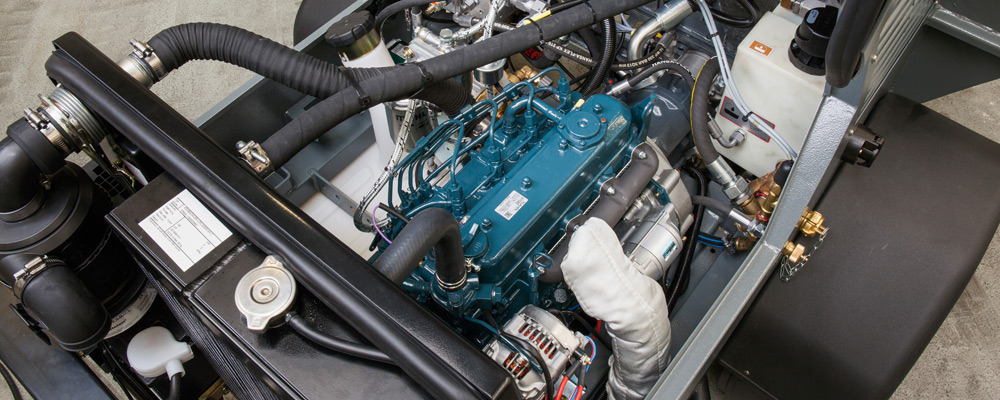

Take care for the hydraulic System

The hydraulic system is considered to be the "blood circulation" of a machine. Disorders in the hydraulic system lead to error functions and usually the complete breakdown of the machine. The main cause of these breakdowns are defective valves or in extreme cases, also the breakdown of the hydraulic pump. These failures are almost always due to dirt in the hydraulic oil. To avoid this dirt, the hydraulic filter is an essential part of the oil circuit. By keeping the hydraulic oil clean, the filter protects the expensive components in the hydraulic system from damage and breakdown.

Clean the delivery hoses

When cleaning, pay special attention that no residue of mortar remains in the delivery hose. Only PM hoses are to be used as they can endure the prescribed operating and testing pressures, and are especially wear resistant.

Check the wear parts

Always keep a check on the wear parts in the machine, wear and tear of which may cause machine breakdown.

In case of any worn or defective parts, get the parts replaced immediately. After completion of each job, make sure that you clean everything thoroughly with water. Lubricate all the necessary points with the help of grease gun.