Our Added-Values at Putzmeister

Learn more about our added-values at Putzmeister: efficiency, connectivity, human-machine interfaces, safety and service.

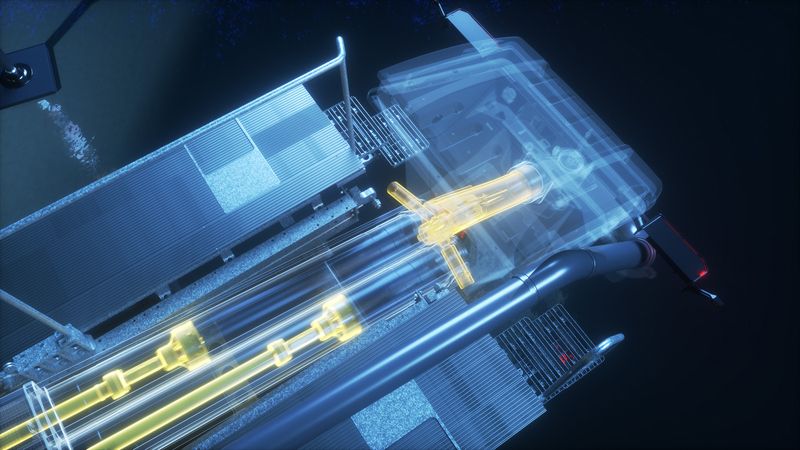

EFFICIENCY AT PUTZMEISTER

Putzmeister machines are powerful and extremely reliable. Our innovations always aim to reduce operating costs and increase efficiency

- More output for less input. Or, save time and money with more power.

- Reduction in overall costs/TCO (Total Cost of Ownership)

Concrete Pumps 17 iLS / 19 iLS - Operate extremely economically and meet extreme challenges!

Special Features

- Fuel savings of up to 25%

- 3 % increased efficiency through the prevention of leaks

- 10 % better suction behaviour thanks to the elimination of constrictions in the concrete flow

- Optimised drive unit

- Maximum performance, minimum operating costs

- Optimised conveying unit – ideal for the the heaviest concretes

- Reduced wear for long service life

- Optimised accessibility for maintenance and service

- Automatic stroke correction without pump interruption

- Field-tested and robust

- Maximum quietness

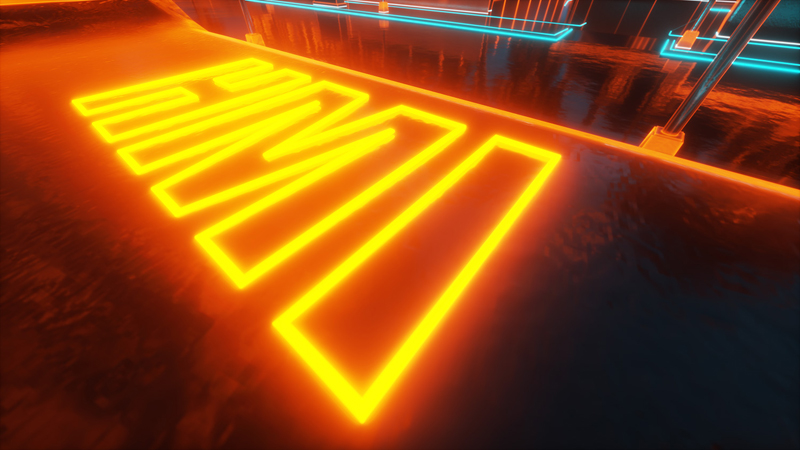

CONNECTIVITY AT PUTZMEISTER

The Putzmeister machine cockpit is the information hub for your machines to call up all relevant information in real time.

- Transparent for more safety and control

- Highly efficient fleet management

- Maximum productivity, safety and service

- Reduces costly downtimes

You want

- Maximum utilisation and availability?

- Increased machine efficiency?

- Investments protected against theft?

Then test our demo version at:

or contact the Putzmeister digital experts at: cockpit@putzmeister.com

HUMAN MACHINE INTERFACE AT PUTZMEISTER

Monitor and control all functions of a truck-mounted concrete pump. For simpler operation, pump monitoring, troubleshooting and maintenance.

- Provides machine operators with optimum support during their work thanks to intuitive, simplified operation – more comfortable, more secure, more efficient

- Machine operators can react quickly if parameters change

Ergonic® 2.0 at a glance

- EPS – Ergonic® Pump System Takes control of the concrete pump, ensuring a fully optimised pumping process

- EOC – Ergonic® Output Control Regulates the optimum engine speed, ensuring that the concrete pump operates smoothly with fuel efficiency and low wear

- EMC – Ergonic® Mixer Control * Operates the mixer drum by radio remote control, including adding water and cleaning

- Ergonic® FFS Ergonomic boom control with joystick, ensuring convenient operation and up-to-date feedback as well as system information for the machine.

- EGD-RC – Ergonic® Graphic Display-(Radio) Remote Control Transparent overview of the pumps and machine status as well as the pump settings, ensuring convenient operation

- EBC – Ergonic® Boom Control Controls and regulates the movement of the concrete placing booms, ensuring an increased placement rate and simple and safe operation.

- ESC – Ergonic® Setup Control The safety system regulates the interaction between the flexible support** and working areas. Provides significantly increased protection for the machine operator and the machine.

(*) PUMI and truck mixer

(**) Availability and functional scope depend on the machine model

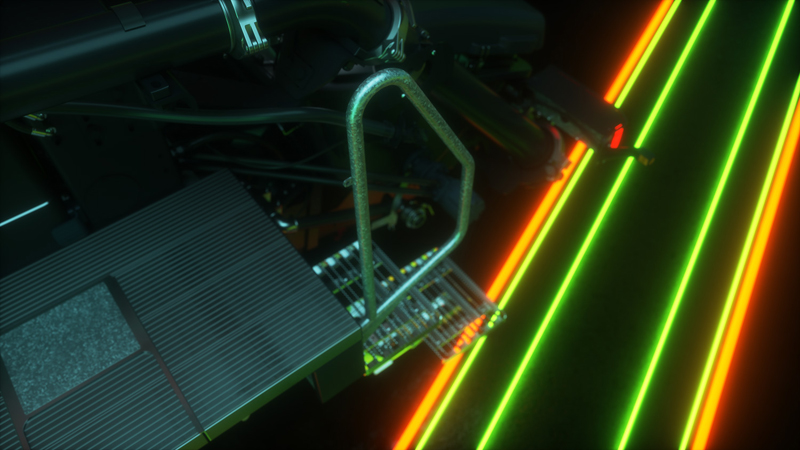

SAFETY AT PUTZMEISTER

Putzmeister offers a comprehensive safety package that meets the strictest standards in order to protect users and their machines – minimum risk, maximum investment security.

Safety at work – Putzmeister standard

- Handrail next to the water box

- Step for cleaning the hopper

- Fixed water box cover

- Defined jack points at the machine

- Definded fall protection anchor points

- Safety cut off at the hopper grille

- Snap lock verification

- Display of the operating range for allowed support leg configurations

- Monitoring of the horizontal support leg position

- Monitoring of the vertical support leg position

- Boom rest with warning device

- Hopper cover

- Wash out lid with ball catcher

- Boom cylinder protection

- Delivery pressure limitation

- Warning and information signs

- Decal for allowed gross hanging weights at the boom tip

Additional safety with optional accessories

- Optional illumination

- Remote control holder with warning signal

- 360°-camera

- Fold down delivery pipe magazine

- Folding rear underrun protection

- Working platform

- Swing out step

- Pedestal hand rail

- Protector for separate end hose connection

- Fill level controlled pumping with indicator

- Proven end hose-accessory

- Spray container

- SH-(steady hose) end hose

Safety through preventative maintenance

- Re-inspection of the machine

- Delivery hose test

SERVICE AT PUTZMEISTER

Putzmeister has an outstanding service network with its own Academy that provides training and continued professional development for operators and Service technicians.

Putzmeister – Service stations always close to you

Your benefits at a glance:

- Optimized processes through accurate, competent advice

- Maximum machine availability thanks to reliable, fast supply of genuine Putzmeister accessories and spare parts

- Long-term value retention through maintenance packages

- Efficiency and investment protection with manufacturer’s training courses and seminars for operators

- Machine downtimes minimized through fast support in case of fault

- Reliable all-round assistance thanks to maximum customer focus with service stations in over 120 countries worldwide

We are at your service: Services@putzmeister.com