High density solids pumps convey fats and floating sludge in Paris waste water treatment plants

19 may 22

Putzmeister high density solids pumps have been pumping dewatered sewage sludge and filter cakes in numerous sewage treatment plants for decades.

The S.I.A.A.P. wastewater association for the greater Paris area also successfully uses Putzmeister pumps to convey fats and floating sludge.

Underneath the two floating sludge There is a double-shaft pre-pressing device under each of the two floating sludge silos, which feeds material via a "Y-pipe" together to the feed hopper of the of the of the KOS solids pump

The sewage association for the greater Paris area, S.I.A.A.P. (Syndicat Interdépartemental Pour L'Assainissement de L'Agglomération Parisienne), has the task of collecting and treating the waste water of 8.1 million inhabitants. The catchment area covers the departments of Paris, Hauts de Seine, Seine St. Denis and Val de Marne - a total area of 1,895 km2. Currently, the S.I.A.A.P. has a total treatment capacity of 2.45 million m3/day, distributed over the following treatment plants:

- Achères plant: 2,100,000 m³/day

- Noisy le Grand plant: 28,000 m³/day

- Valenton 1 plant: 300,000 m³/day.

Paris Achères wastewater treatment plant, general view

High proportion of floating sludge and fats in Paris wastewater.

As there is hardly any pre-treatment with separators in the S.I.A.A.P. catchment area, Parisian wastewater contains a comparatively high proportion of floating sludge and fats. In the Achères treatment plant alone, between 8 and 12 t of floating sludge have to be treated every day.

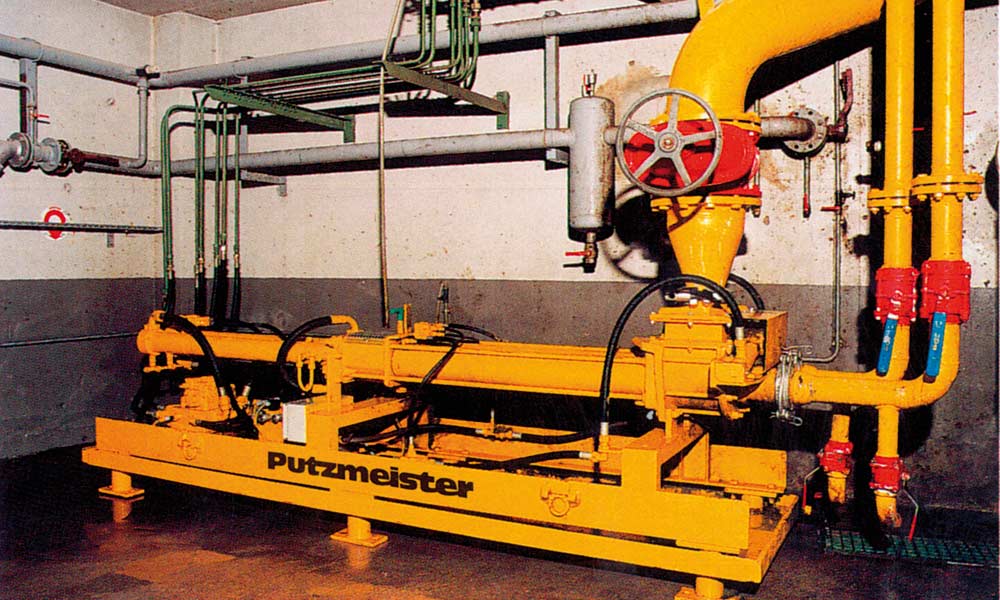

A KOH 1030 double piston pump with a double outlet conveys the fats into the deck oven

The floating sludge separated by grease separators has a relatively stiff consistency. The material is first stored in two silos, each of which has a double-shaft Putzmeister THS 222 HCB pre-pressing device underneath. The two pre-pressing devices draw the material from the silos and feed the floating slurry together through a so-called Y-pipe to the feed hopper of a Putzmeister double piston pump KOS 1030. They have two other important functions: On the one hand, they prevent the material from bridging when it is drawn off from the silos, and on the other hand, they ensure a high filling level of the thick matter pump delivery cylinders.

Every day at the Achères sewage treatment plant 12 t of floating sludge with a relatively stiff consistency treated

The pump conveys the scum via a rotary distributor into a truck that picks up the material outside the pretreatment plant and transports it to two fluidised bed furnaces 4.5 km away. There, the floating sludge is burnt together with the methane gases from the grease separators.

Investigations are currently underway to also cover the distance of 4,500 m between the grease separators and the incineration plant with a Putzmeister pump. Initial experience shows that this conveying distance is quite realistic when using a powerful thick matter pump.

Combustion temperature automatically regulates the high density solids pump feed into fluidised bed furnaces

Already since 1982, the fats from the pre-treatment have been fed into a fluidised bed furnace at the Achères sewage treatment plant by a Putzmeister KOR 542 pump. A second furnace was put into operation in 1993. In the course of the sewage treatment plant extension, two modern Putzmeister KOS 1030 were integrated into the plant. Depending on the incineration temperature level, a certain amount of scum is injected directly into the fluidised bed furnace by the KOSdouble piston pumps (conveying distance approx. 10 m). Since delivery rates of a maximum of 1 m³/h occur, Putzmeister has deliberately designed the delivery rate of the two KOS 1030 pumps to be low. The delivery pressure is only low with this material and at this distance. The analogue control via a 4 - 20 mA signal and a proportional valve of the KOS pumps make it possible to control the grease feed into the fluidised bed furnace depending on the momentary combustion so that the furnace can be operated at a constant temperature.

High density solids pump conveys sewage sludge into multi-deck furnace

Unlike the Achères sewage treatment plant, the Noisy plant has a multi-deck furnace in which the dewatered sewage sludge from the plant is incinerated. The sewage sludge is dewatered by centrifuges to a variable dry matter content of 25 to 28 %. A thick matter pump of the type KOS 1030 with double outlet then conveys the filter cakes into the furnace via two injection lances. Putzmeister has equipped the high density solids pump with an automatic control system that adjusts the delivery rate to the fluctuating filter cake volume of the centrifuge; it varies between 1.5 and 3 m³/h. With a delivery line length (DN 100) of approx. 30 m, the pump pressure in the medium is between 25 and 40 bar. The screenings pass through a pneumatic chamber into the deck kiln via a belt conveyor.

Satisfied customers place follow-up orders

The operators of the Noisy plant are satisfied with the function and reliability of the KOS pump: After 10,000 hours of operation, Putzmeister received an order for the delivery of another KOS pump to convey sewage sludge filter cake. S.I.A.A.P. is also obviously impressed by the high availability of the Putzmeister pumps. In the newly built Colombes sewage treatment plant, which also belongs to the wastewater special purpose association, 12 seat valve-controlled HSP high density solids pumps and five silo discharge systems are installed.