Sludge handling equipment from Putzmeister in Waste Water Treatment Plant Czajka/Poland

May 10, 22

Sludge handling equipment from Putzmeister in Waste Water Treatment Plant Czajka/Poland

Veolia Water was awarded the contract for the third phase expansion and modernisation of the Czajka WWTP, in February 2008.

The consortium responsible for project delivery comprised Veolia, Warbud, OTV, Kruger and WTE Wassertechnik, with plant automation being provided by Siemens. The client was the Miejskie Przedsiebiorstwo Wodociagów i Kanalizacji w Warszawie (Warsaw Water and Wastewater Company).

Warsaws biggest WWTP “Czajka” was extensively extended beginning from 2008 on. After serveral years of construction, upgrade and extension the new wastewater treatment plant started its operation. With a Population equivalent of appr. 2,1 mio and a daily capacity of wastewater of more than 435.000 m³ it is now one of the largest WWTP´s in eastern Europe and working in line with European standards.

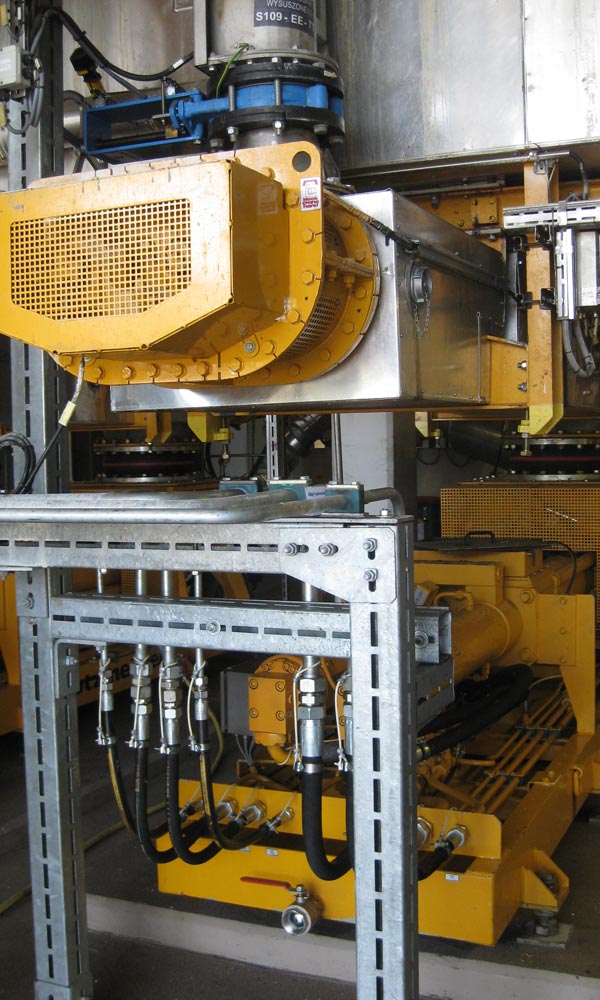

Twin feeding screw SHS 2442 SH delivers the sludge out of the concrete silo into a KOS 1080 piston pump with service gate valve

The extensive refurbishment also included the sludge handling and dewatering of the sewage sludge. By new centrifuges the municipal sludge is dewatered to a dry solid content of approx. 25 % and is then stored in three concrete storage silos of each 530 m³ volume.

Receiving bunker to receive sludge by trucks from an intermediate emergency storage

SHS 3242 SH twin discharge screw KOS 1080 piston pump below 30 m3 sludge receiving bunker

Putzmeister was chosen to be the supplier for the sludge handling equipment for this large project. The scope of supply for Putzmeister were the embedment parts for the concrete silos, the sliding frames for the storage silos to discharge the sludge out of the storage silos into a twin screw auger feeder which feeds the Putzmeister KOS type piston pump with the well proven S-tube technology. All is driven by a hydraulic power pack and controlled by PLC, also provided by Putzmeister.

In addition a 30 m³ sludge receiving bunker incl. sliding frame, twin discharge screw, piston pump, hydraulic power pack and control cabinet were supplied and installed by Putzmeister. This enables the wastewater treatment plant to also receive sludge delivered to the plant by trucks.

The two KOS 1080 piston pumps below the storage silos are transferring each up to 20 m³/h of the mechanically dewatered sludge over a distance of approx. 120 m through a high pressure pipeline to the drying and incineration part of the plant. To increase the flexibility of the pumping system and to decrease the energy consumption an BLI (Boundary Layer Injection) system was installed. By using the same polymer suspension as for the conditioning of the sludge the friction in the pipeline can be reduced to a minimum. This results not only in reduced energy consumption but also reduces the wear of the pumping system significantly. Depending on the type of polymer the pressure loss can be reduced by around 50 % (or even more..!!).

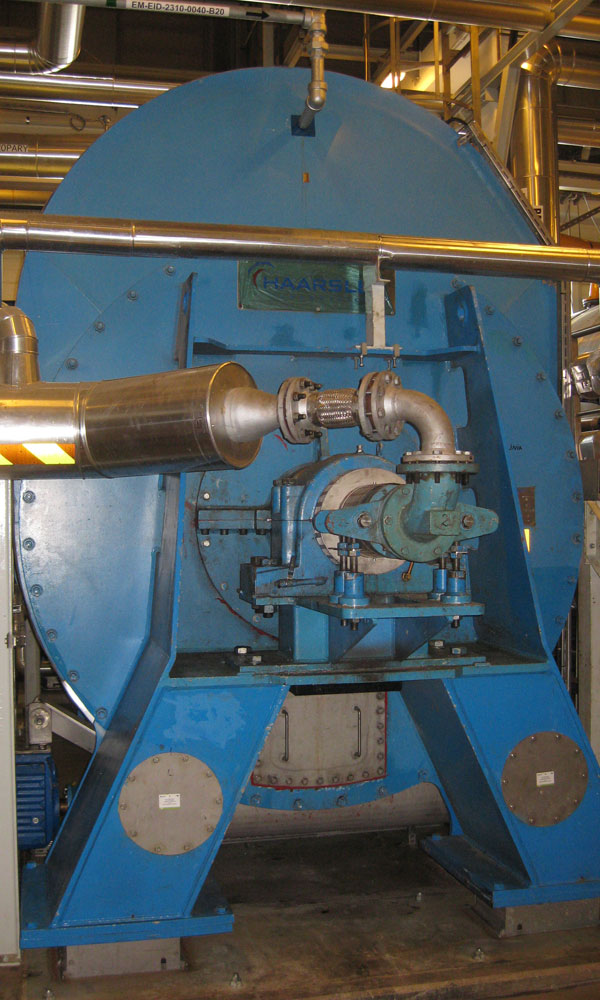

The sludge is pre-dried in two disc dryers to approx. 35 % dry solid content at 90 °C. The sludge is dropped from the two disc dryers into a 20 m³ intermediate storage bunker which is fully insulated to maintain the temperature. The hot and pre-dried sludge is then discharged by a Putzmeister sliding frame into two twin screw feeders. The twin screw feeders are equipped with an additional opening at the one end of the twin screw. At this opening full dried sludge (95 % DS) is dosed into the pre-dried sludge. On the trough of the twin screw feeder additionally dosing points for grease trap material were installed.

The mix of these three materials is fed then into two KOS piston pumps in special high temperature design. To extend the lifetime of the sealing and wear parts all sealings are made of a high temperature resistant material. The S-tube socket is equipped with a special cooling device as well as the water box between the delivery cylinders and the hydraulic cylinders. These two pumps feed the two fluidized bed incinerators which are located approx. 55 m away. The Putzmeister piston pumps have proven their high availability for transporting hot sludge even including full dried sludge.

Twin feeding screw SHS 1732 SH to feed hot sludge into the KOS piston pump. Full dried sludge dosing at the rear end of the twin feeding screw.

Twin feeding screw SHS 1732 SH to feed hot sludge into the KOS piston pump. Full dried sludge dosing at the rear end of the twin feeding screw. Disc dryer to pre-dry the sewage sludgebefore incineration

Emergency truck loading station

BLI preparation and dosing station incl. control cabinet

Extension of the sludge handling system at WWTP Czajka

In 2016/2017 the sludge handling system of the WWTP Cajka was extended by a third concrete storage silo. Again Putzmeister supplied the machinery equipment for this plant extension.

Total scope installed – Technical data

| Sludge dewatering | Sludge incineration | |

|---|---|---|

| Medium | mechanically dewatered municipal sewage sludge |

predried municipal sewage sludge |

| Dry solids content | 25 % | 35 % |

| Temperature | - | 90 °C |

| Precipitation | by polymer | - |

| Dewatered | by centrifuge | - |

| Delivery rate | 20 m³/h (each pumping line) | 10 m³/h (each pumping line) |

| Storage capacity | 3 x 530 m³ concrete silos | 1 x 20 m³ (steel silo) |

| Sludge handling equipment |

3 x silo discharge sliding frame 3 x twin feeding screws 3 x KOS piston pumps 3 x hydraulic power packs 3 x control cabinets 1 x boundary layer injection unit (BLI) |

1 x silo discharge sliding frame 2 x twin feeding screw 2 x KOS piston pump 2 x hydraulic power pack 2 x control cabinet |