WWTP Oftringen (CH) – Sludge reception and storage bunker

May 13, 22

Putzmeister high density solids pump KOS 1040 HP with S-tube handling dewatered sewage sludge even containing foreign bodies from sludge reception to incineration.

Task

The erzo association (acronym for Waste Disposal for the Region of Zofingen) has operated a sludge treatment plant for many years. Since the volumes of sludge generated in the region are continuously increasing, a new, larger sludge treatment plant was opened in 2008. The plant consists of two new concrete silos each with a volume of 175 m3 that are used simultaneously as a reception and storage silo. Both concrete silos are equipped with the tunnel version of a Putzmeister sliding frame system, which conveys the sewage sludge to the discharge and auger feed devices installed under the silos. Each of these dual-shaft auger feed devices loads a KOS type Putzmeister piston pump, which pumps the sewage sludge approx. 110 m into a rotary kiln for incineration.

KOS type piston pump set-up beside the concrete silos

The decision for Putzmeister was made because of the technical concept which has been developed for such special concrete silo systems. Another reason was the low maintenance cost of Putzmeister equipment proven in the WWTP Pro Rheno in Basel.

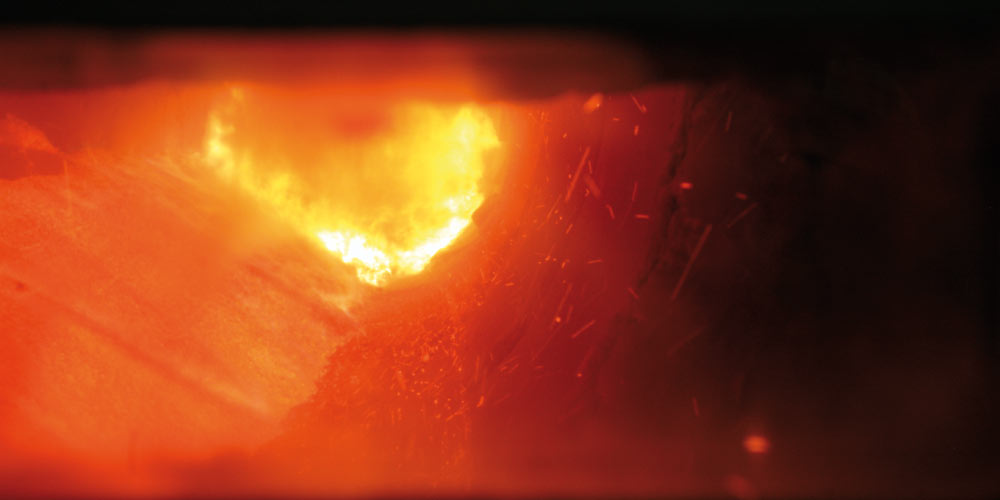

Rotary kiln for incineration of sewage sludge

Material transport

The dewatered sewage sludge is delivered with trucks to the plant and will be discharged into the two concrete silos. A Putzmeister sliding frame discharges the sludge to a twin screw auger feeder which feeds the Putzmeister high density solids pump that then pumps the sludge through a DN 150 pipeline over approx. 110 m into the rotary kiln.

Medium

Mechanically dewatered municipal sewage sludge with a AS-content of 25 – 40 %.

Equipment

- 2 x Silolid (Butterfly type), hydraulically driven

- 4 x sliding frame PDL 6027

- 2 x silo discharge screw

- SHS 5542 SH LCB (low cross booster)

- 2 x high density solids pump KOS 1040 HP LCB

- 1 x BLI unit

KOS series...

Especially at reception bunkers for foreign sludges the KOS piston pump has proved its high reliability. Since those sludges can contain most likely any type of foreign bodies like stones, wood pieces, etc. the KOS piston pump without valves will guarantee a continuous process. Even particles with a size of up to 80 % of the outlet diameter can be conveyed.

BLI – injection unit for lubrification of the pipeline if pressure loss is rising

Process data

Output: 5 m³/h

Delivery pressure:

Operating pressure: 60 – 80 bar

Max. theo. pressure: 100 bar

If the delivery pressure rises in the delivery line it is possible to reduce the pressure loss again by injecting a boundary layer liquid (water or polymer) via the BLI unit. This will help to save energy while pumping.

HA 75 E Electric power pack

Silo lid, sliding frame PDL 6027, discharge screw SHS 5548SH