Saving Energy Costs by using alternative fuels in Cement Kilns – South Africa

Apr 25, 23

Saving Energy Costs by using alternative fuels in Cement Kilns – South Africa

How it works

Material from waste suppliers like refineries, cosmetic and food companies including Heavy ends is collected and transported to a blending platform to produce the correct blend for the correct application.

How Putzmeister can help

The Putzmeister Industrial Technology can build a system to unload, mix and reload into tankers for delivery to cement sites. Type KOS and KOV units are used for this application.

The Pumping system

The KOS unit is then used to pump the material into the kilns at a rate that varies between 1 – 7 cubes/hour depending on the production rates.

Co-incineration of alternative fuels helps reducing coal costs and gas South Africa

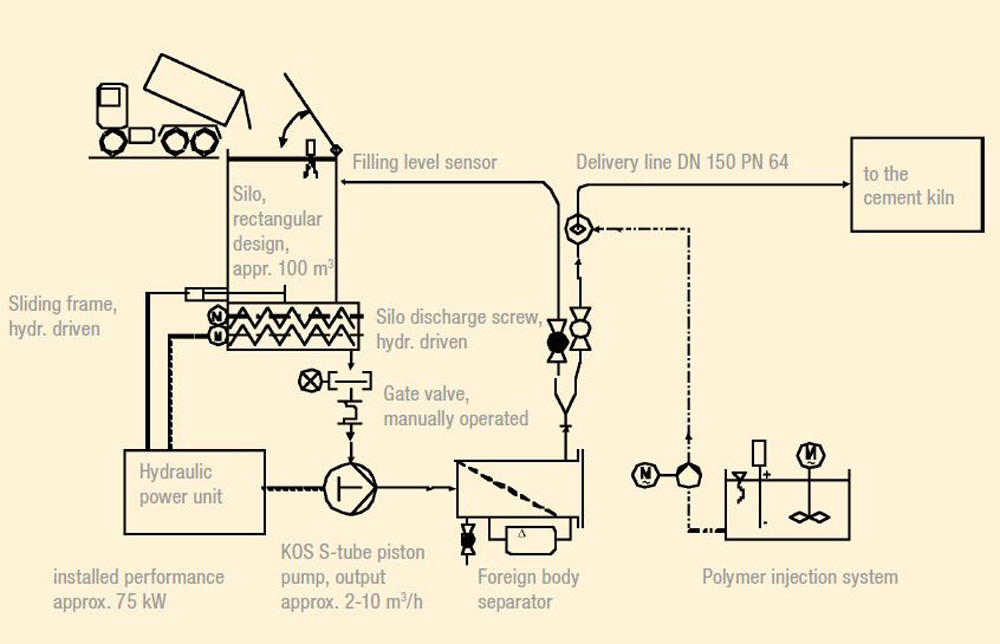

Example for a possibility of a sludge handling station

■ Thanks to the large storage volume for the alternative fuel, the cement kiln can now be continuously charged – even at weekends and during holidays, when there are no deliveries of replacement fuel.

■ Different sludges can be fed into the high density solids pump and mixed together by the pump’s rotate function.

Values

Saving money

Reducing consumption of coal or gas.

Saving environment

Waste to energy. Disposal of non-recyclable waste to a high standard and utilizes its energy content. It also avoids environmentally damaging landfilling of waste.

Ensures strong competitiveness

By providing silos and pumps to receive and supply alternative fuels, to produce reasonable priced cement for all kind of construction works.

What makes Putzmeister special

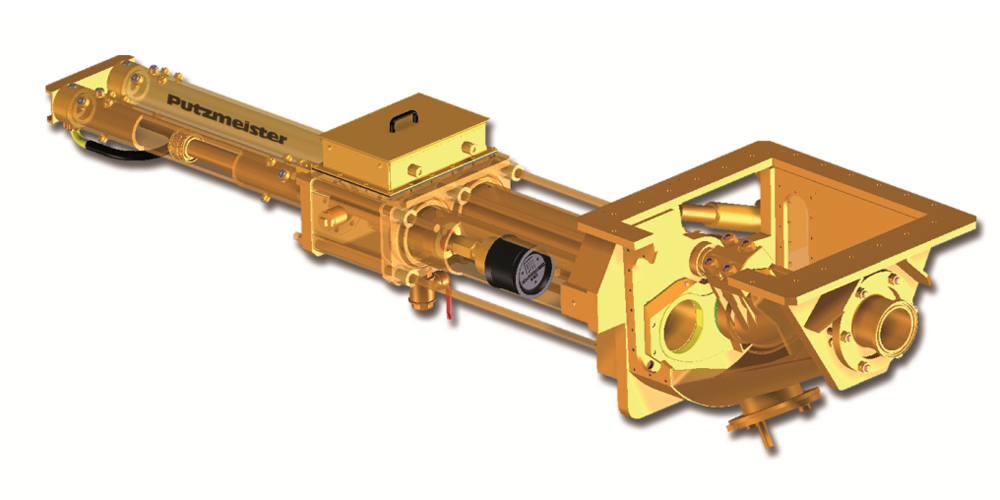

KOS S-transfer tube

The large unrestricted S-transfer tube cross selection does not present a problem for considerably large foreign bodies with a size of up to a maximum of 70% of the pressure connection diameter can be pumped.

KOS high density solids pump with S-transfer tube

Machine Equipment |

|

|---|---|

| KOS S-tube piston | |

| Foreign body separator | |

| Hydraulic power unit | |

| Control Cabinet |

Optional Equipment |

|

|---|---|

| Silo | |

| Sliding Frame | |

| Silo discharge screw | |

| Foreign body separator |

Hydraulic Power unit at Interwaste, Johannesburg

Putzmeister References in South Africa:

■ Interwaste collecting and mix material at blending Platform – Johannesburg

■ Kaalfontein Blending Platform for Lafarge – Johannesburg

■ Lafarge Cement Factory – Lichtenburg

■ Afrisam Dudfield – Lichtenburg