Sewage sludge incineration with domestic waste

May 18, 22

Sewage sludge incineration with domestic waste

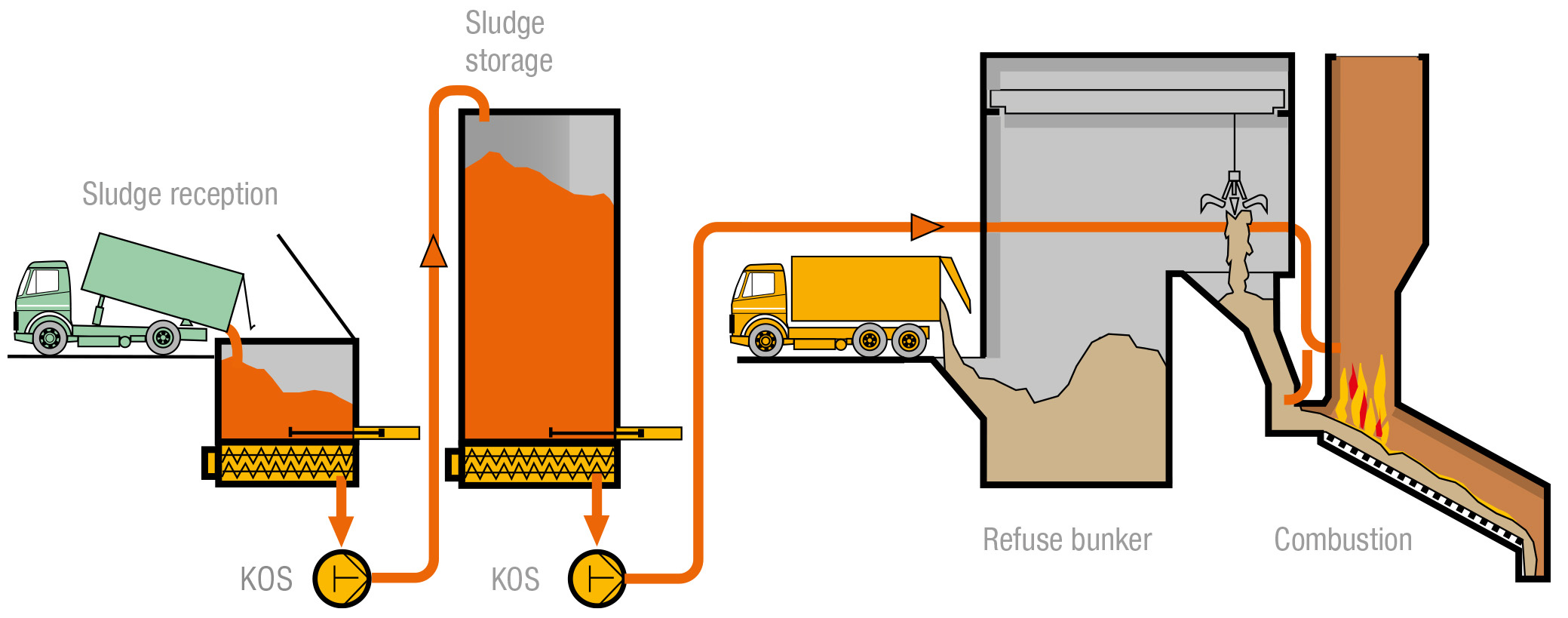

The disposal of dewatered sewage sludge is an important point nowadays in refuse disposal. A very environmentally-friendly and favourably-priced possible disposal is burning it along with dewatered sewage sludge in household waste incinerators.

Existing projects show that when both are burnt together that this does not lead to higher emissions, that the investment costs are low and that the sludge can be disposed of in an environmentally-compatible manner and economically. Putzmeister offers turn-key complete solutions for storage, transport and the feeding of refuse into the combustion chambers.

The disposal of sewage sludge along with the incineration of household waste can be integrated both in newly planned plants as well as retrofitted in older plants. The addition of sewage sludge in no way impairs the reception of household refuse or the discharge and metering of waste into the combustion chambers. Apart from the fact that both are burnt jointly, there is no interface between the disposal of both.

Whereas the traditional incineration of sewage sludge (mono incineration) is carried out in fluidized bed incinerators which requires large-scale flue gas dust collection when the sewage sludge is burnt along with the domestic waste, no additional cleaning of waste gases is required as the equipment available is sufficient and can be utilised.

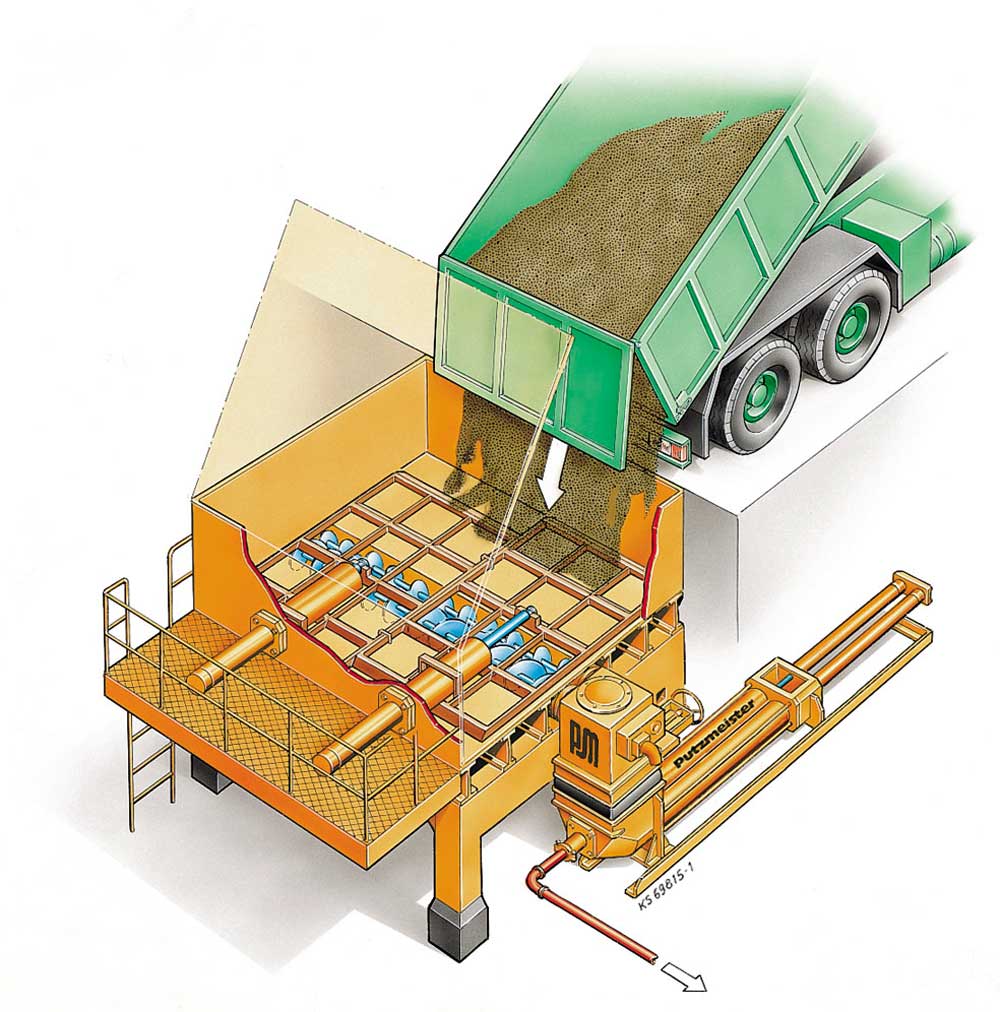

The delivery of the dewatered sewage sludge is carried out in a separate reception bunker by truck. The size depends upon the incineration capacity and is usually between 40 and 200 m3 . The reception silo is the intermediate storage place, resp. the “buffer” for the sludge that is delivered at irregular intervals.

Uniform feeding of sewage sludge into the incineration process

As the incineration of refuse ought to be carried out as continuously as possible so as to avoid peaks in temperature and pollutants, it is imperative that the sewage sludge is fed uniformly.

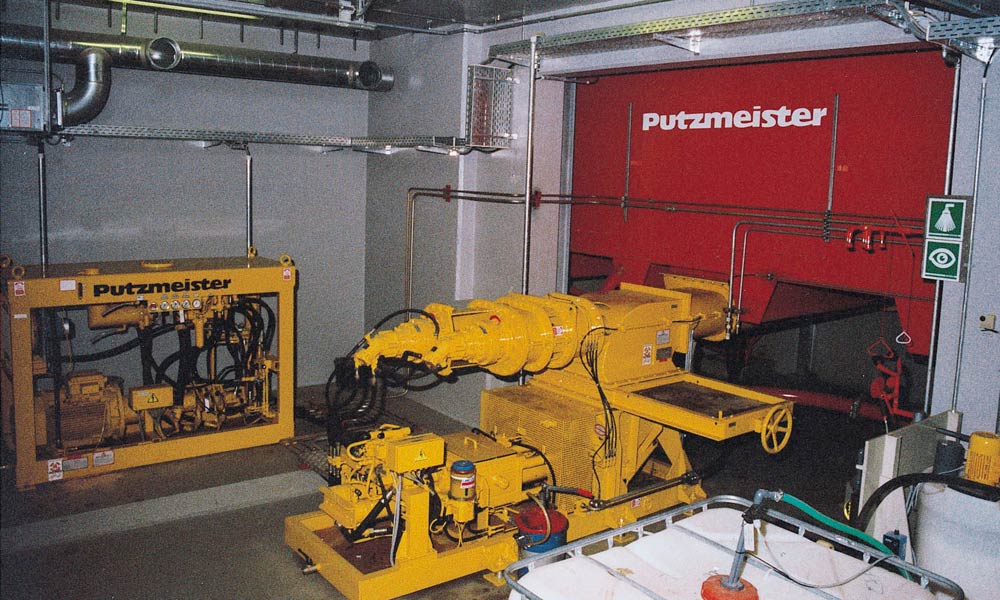

Above: 60 m³ reception silo with injection pump KOS 540 and power pack HA 45 in the refuse heating and power station at Vestkraft, Copenhagen, Denmark

The sewage sludge is discharged out of the silo by a sliding frame that is on the floor of the silo and which guides the sludge into the feeding device of a connected high density solids pump. As solids such as stones, glass and other foreign bodies are found time and time again in the sludge, Putzmeister recommends the use of valveless high density solids pumps of the KOS series. Due to its design, this pump solution is able to convey foreign bodies up to a size of 2/3 of the discharge outlet diameter. This guarantees the highest degree of availability of the plant. These transfer tube-controlled pumps then take over the conveying of dewatered sewage sludge into the combustion chamber of the incinerator which is frequently several hundred metres away. If the foreign particles in the sludge are undesired they can be extracted by a simple foreign body separator.

KOS pumps deliver sludges of different consistencies

An important advantage of the pump technology compared to traditional conveying systems is that sludges with completely different consistencies can be pumped and homogenizing is not necessary. The high density solids pumps require both adhesive, fluid, plastic and compact sewage sludges.

Above:The solids pump KOS 540 conveys over 80 m into the incinerator of the refuse power station at Vestvorbraending, Copenhagen, Denmark

As only approximately 10 – 15 % of the total material incinerated is sewage sludge, the fluctuating consistency of the sludges (they generally derive from different sewage plants) has no important influence on the process of incineration.

Transport of high density solids via closed pipelines

The conveyance of high density solids by pumps is carried out via a closed and static pipeline. This means that odour nuisance is avoided and also the vicinity is not contaminated which cannot be avoided with traditional transport systems such as belt or auger conveyors. The length of the delivery line between the silo and incineration plant can be several hundred metres. It is therefore also dependent upon the spatial factors on site. As the pipeline can be laid both vertically and at 90° elbows, the delivery line adapts to the respective building structure within the plant. If especially great distances have to be bridged, then the injection of a boundary layer is recommended. The friction in the pipeline is thereby considerably reduced. At the same time the necessary delivery pressure sinks so that when sludge is also conveyed over several hundred metres the complete system consisting of pump and delivery line is preserved and less drive performance is required. Only 0.5 % to 1 % of the total amount to be conveyed is injected in the form of a fluid (polymer solution or water). The boundary layer fluid injection, by the way, is also used for the conveying of highly dewatered filter cake (e.g. 40 % dry solids content).

Above: Reception area at Sarcelle, France

Above: Truck reception silo with high density solids pump

The sludges can be charged by high density solids pump into the incinerator in very different ways. Proven to be technically very favourable is the conveying and injection of high density solids with the help of nozzles, resp. charging lances:

- into the shoot, or

- directly into the combustion chamber.

The optimal charging technology depends upon the technical factors of the method such as the percentage share of sewage sludge, domestic refuse, the required loss on ignition, etc.

Above: Insulated delivery lines from the reception to the incinerator building

The high density solids pump makes a metered charge of the sewage sludge possible dependent upon the incinerating temperature in the combustion chamber. This leads to an optimized incineration process.

Putzmeister has supplied multiple, turn-key plants for the co-incineration of dewatered sewage sludge in refuse incineration plants. They consist of high density solids pumps, silos and delivery lines including the mounting and setting into operation. These plants are working successfully and to the full satisfaction of the customers. The plant components were individually matched to the conditions and requirements of the respective incineration plants.

Reference installations were also supplied to:

- Vadec La Chaux de Fonds, Switzerland

- KVA Horgen, Switzerland

- Sarcelle, Dinan, Cenon, Astria, France

- Vestforbrænding, Vestkraft, Denmark

- Taoyuan, Republic China/Taiwan

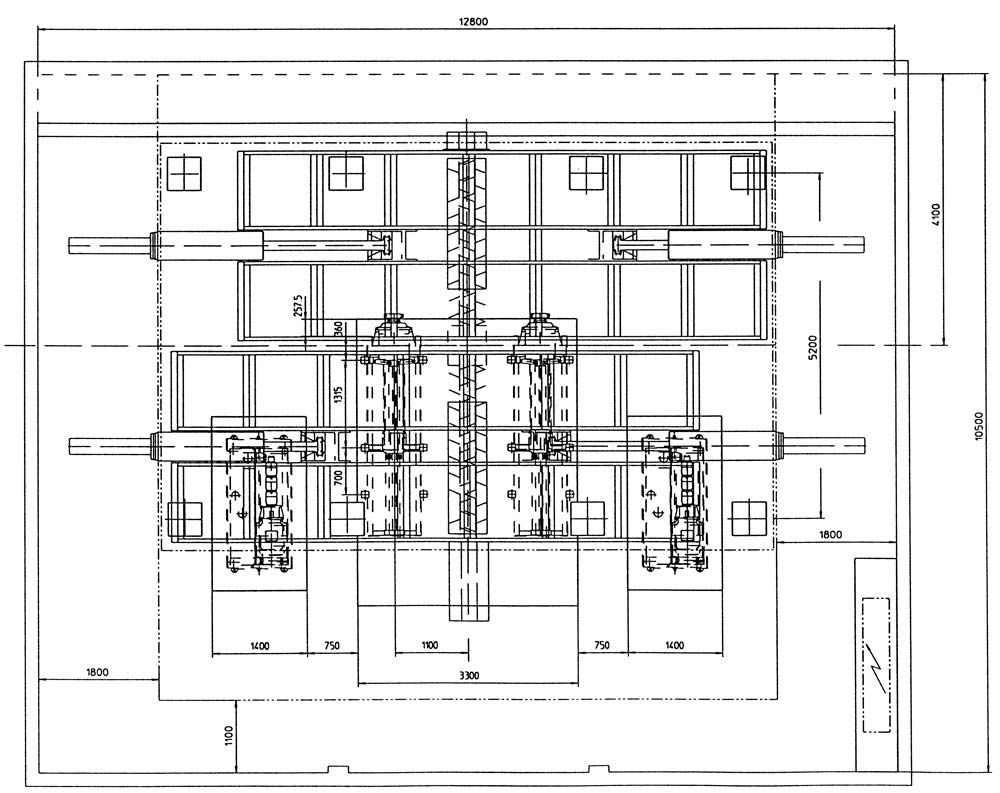

Above: Two high density solids pumps KOS 1030 with HA 22 for charging sewage sludge into the refuse incinerator at Dinan, France