Back to Overview

MT 1 0

Mixing technology at its best

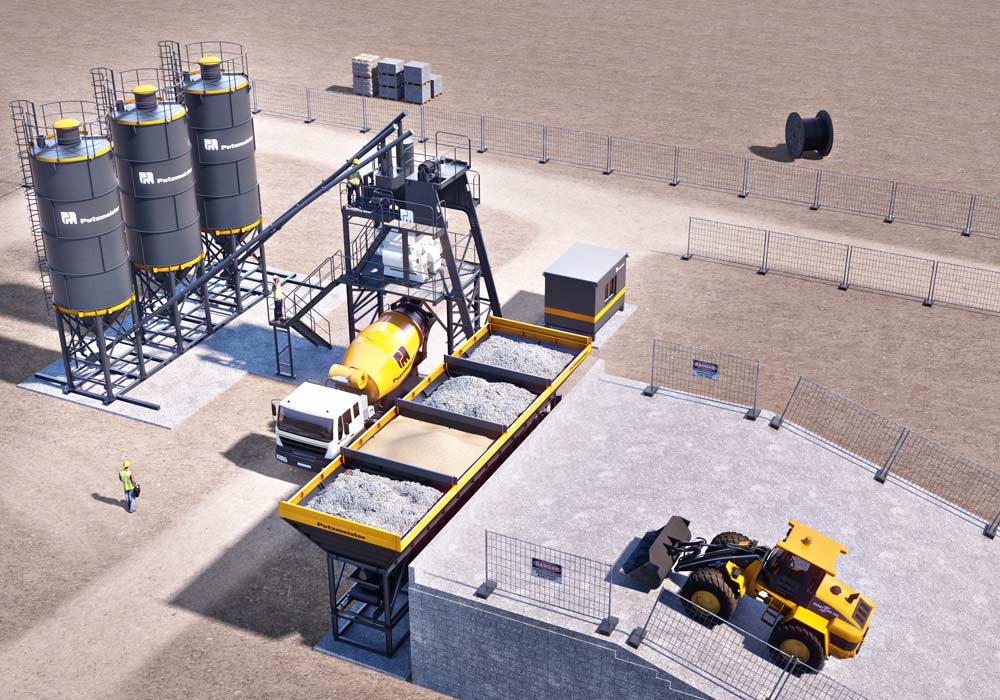

The 60 m³/hr batching plant from Putzmeister has been engineered to meet the requirements of commercial RMCs, real estate and infrastructure projects.

Putzmeister uses the best of German engineering to design and manufacture batching plants that meet the requirements of the global construction industry in this category. Available in the widest range of variants in this category of batching plants, the MT 1.0 offers high productivity, fully automated operation, ease of maintenance and a clean and safe working environment.

This plant is equipped with a twin-shaft mixer to ensure the fastest maximum mix quality.

Key Features

- Configurable to meet any job site requirement

- Choice of different aggregate storage types

- Consistent, homogenous mixture with every batch

- Easy drive-through, TMs don’t have to drive in reverse

- Modular design for faster installation

- Easy mobility between job sites

- Fastest maximum mix quality with twin-shaft mixer

- Automated central lubrication system for smooth running of mixer

- The top weighing system for cement, water and fly ash ensures accuracy at all times

- Preventive maintenance and interlocks in the control system

- Hood for inclined belt conveyor for cleaner aggregate movement

- Maintenance platforms with easy access to mixer, weighing systems and all other equipment

General Information

-

Operating Voltage - Frequency415/50 V/Hz

-

Automatic Batch ControlPC / Software

Configuration

- MT 1.0 Skip & Inline Bins

- MT 1.0 Inclined Belt Conveyor & Inline Bins

- MT 1.0 Skip & Compartment Bins

-

Plant Capacity60 m³/hr

-

Space Required (L x W)27 x 5 m

-

Plant Height (without Silo)10.8 m

-

Concrete Discharge Height4x1 m

-

Mixer TypeTwin Shaft TS 1.0

-

Operating Voltage - Frequency415/50 V/Hz

-

Input Power18.5 x 2 kW

-

Dry Filling1.5 m³

-

Compacted Concrete1.0 m³

-

Weighing System - Cement750 kg

-

Weighing System - Water250 kg

-

Weighing System - Additive15 kg

-

Compressor9 bar

-

Pressure Tank Volume300 l

-

Aggregate Storage - No. of Compartments (Std)4

-

Capacity of each Compartment12.5 m³

-

Total Capacity (Std)50 m³

-

Batching Gate per Compartment1

-

Filling Width per Compartment3 m

-

Filling Height4.2 m

-

Automatic Batch ControlPC / Software

-

Plant Capacity60 m³/hr

-

Space Required (L x W)45 x 5 m

-

Plant Height (without Silo)10.8 m

-

Concrete Discharge Height4.1 m

-

Input Power18.5 x 2 kW

-

Dry Filling1.5 kW

-

Compacted Concrete1 m³

-

Weighing System - Cement750 m³

-

Weighing System - Water250 kg

-

Weighing System - Additive15 kg

-

Compressor9 kg

-

Capacity of each Compartment10/15** m³

-

Total Capacity (Std)40/60** m³

-

Batching Gate per Compartment1 m³

-

Filling Width per Compartment3.2 m

-

Filling Height4.2 m

-

Automatic Batch ControlPC / Software

-

Plant Capacity60 m³/hr

-

Space Required (L x W)37 x 5 m

-

Plant Height (without Silo)10.8 m

-

Concrete Discharge Height4.1 m

-

Operating Voltage - Frequency415/50 V/Hz

-

Mixer TypeTwin Shaft 1.0

-

Input Power18.5 x 2 kW

-

Dry Filling1.5 m³

-

Compacted Concrete1.0 m³

-

Weighing System - Cement750 kg

-

Weighing System - Water250 kg

-

Weighing System - Additive15 kg

-

Compressor9 bar

-

Pressure Tank Volume245 l

-

Aggregate Storage - No. of Compartments (Std)4

-

Capacity of each Compartment12.5 m³

-

Total Capacity (Std)50 m³

-

Batching Gate per Compartment1

-

Filling Width per Compartment3 m

-

Filling Height5.2 m

-

Automatic Batch ControlPC / Software